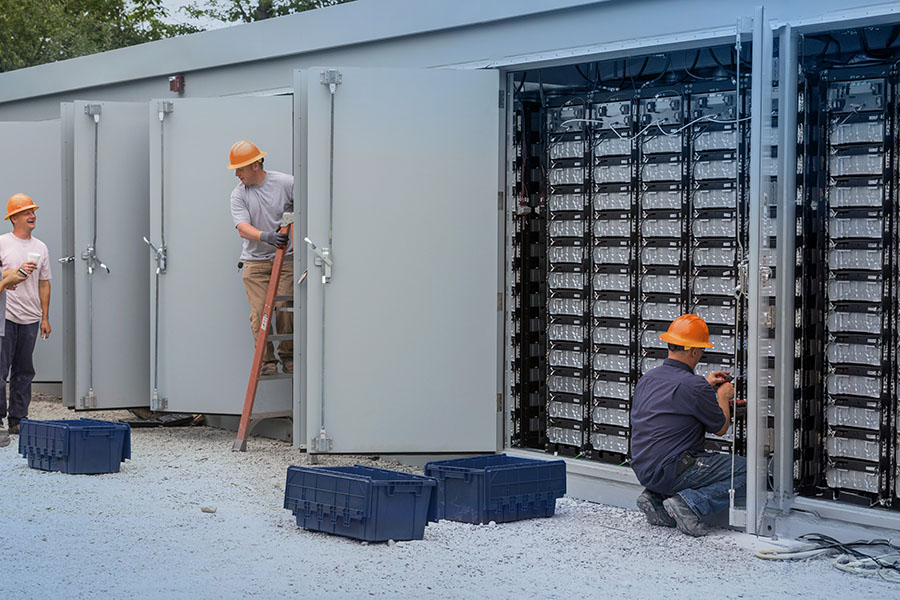

Act Early, Ensure Safety: Optimize BESS Performance and Reliability

In the evolving energy storage landscape, ensuring BESS reliability and safety before commissioning is essential. Operational issues often arise shortly after going live due to underlying problems in subsystems, racks or modules, resulting in costly downtime and safety risks.

At volytica, our digital FAT / SAT commissioning solution meticulously checks 100% of your plant's batteries, identifying and addressing anomalies before the system goes live. This proactive approach not only saves time and money but also enhances overall site success.

100% Test Coverage

Seamless Data Exchange

Results within 24 Hours

Early Issue Resolution

Essential Battery KPIs for FAT / SAT

To optimize battery system performance and longevity, we analyze raw data such as current, power, temperature and state of charge, generating key performance indicators (KPIs) with our advanced algorithms:

Capacity

Verify expected capacity versus available capacity.

Resistance

Identify wiring, connector, cell defects or other electrical issues.

Round Trip Efficiency

Verify expected versus actual efficiency.

Thermal Performance

Evaluate thermal behavior, performance and anomalies.

Safety Limits

Verify compliance with safety-critical limits.

Imbalances

Detect critical charge and thermal imbalances between units to detect hidden defects.

Strategic Advantages for Stakeholders:

Enhancing Quality Control with BESSential:

A Partnership with Sinovoltaics

Utilize BESSential, our comprehensive quality control service for battery energy storage systems (BESS) and benefit from our partnership with Sinovoltaics.

Most powerful analysis: The collaboration combines Sinovoltaics' expertise in factory audits and acceptance testing (FAT / SAT) with volytica's advanced diagnostics algorithms.

As a result, we provide unparalleled insight into battery quality and maximize the efficiency and reliability of BESS projects. Take advantage of a thorough 100% inspection of battery packs, guaranteeing optimal performance and safety from production to deployment. Learn more about our partnership!

Head of Business Development

Discover Battery Monitoring and Benefit from Personal Consultancy

Explore our tailored support for the seamless commissioning of your battery energy storage system and receive expert advice on your specific requirements for successful FAT / SAT commissioning.

Don't miss our latest news on company updates, events and products.