The Magic of Battery Data: Safety & Efficiency in Electric Public Transport

*Originally published in German by Nahverkehrs-praxis, Issue 05-2024

Electric buses are conquering our roads worldwide, and for good reason! They reduce emissions and promote sustainable mobility. But public transportation is facing new challenges. There are questions about total cost of ownership and fire safety. This is where innovative solutions come into play to overcome these challenges and make electric public transport safer and more efficient. VDV’s pioneering initiatives to provide battery data and advanced battery analysis technologies are paving the way for a paradigm shift in public transport management.

VDV Initiatives to Provide Data on Batteries

The lithium-ion battery is at the heart of this mobility revolution – and at the same time by far the most expensive, most complex, and perhaps also the strangest wearing part in recent industrial history. Understanding its performance and ensuring its safety is therefore of central importance. This has already reached the core of the German industry discussion, not least thanks to VDV initiatives such as leaflet 8003[1].

Most fleet management and telematics systems are capable of transmitting these minimum data sets cost-effectively and at the required resolution.

There is now a long list of vehicle manufacturers who provide their customers with the required data. Last but not least, larger transport companies in Germany and abroad are now defining VDV238[2] compliance as a non-negotiable tender condition, thus making a significant contribution to increasing transparency.

Shortage of Skilled Workers and Automation

The European Union[3] estimates that up to 800,000 jobs in the European battery value chain will go unfilled by 2025 due to a shortage of skilled workers and the fact that, although the training of new professionals is steadily improving, graduates naturally lack practical experience.

How to solve the problem when gigabytes of battery data are generated per vehicle per month? Even medium-sized cities now have fleets of several hundred vehicles. The best data scientists and electro-chemistry experts are stretched to their limits. It is a challenge to detect wear patterns, impending failures, creeping defects, or even a risk of fire in a repeatable and reliable manner, especially outside of working hours.

Today, software solutions are available that automate and continuously transform the valuable flood of data into even more valuable insights and alerts. This allows the experts in the organization to focus on interpreting and responding to unplanned events.

Effective Monitoring and Analysis – The Magic of Battery Data

Battery systems contain a large number of sensors and electronics, including the battery management system (BMS). This system performs basic monitoring of the battery and its individual components locally in the vehicle, such as estimating the state of charge or checking general thresholds. However, the complexity of lithium-ion batteries shows that local monitoring alone is not sufficient.

For example, various internal cell processes can only be detected very subtly and over months in the signal interplay between current and voltage, but not in temperature – similar to the gradual clogging of a cable or the slow oxidation of contacts. The local BMS will issue a warning at the latest when a serious problem becomes apparent. However, there is often no time to react, considering that a thermal runaway, for example, occurs within a few seconds.

The complexity of batteries, the limited storage and computing capacity of the BMS, and the difficulty of integrating long-term knowledge mean that potential problems go undetected by the BMS.

The solution is centralized data analysis using battery monitoring software such as volytica. The field data, based on raw values from the BMS, allows for more cost effective, accessible and understandable analysis than in the vehicle. Anomaly detection algorithms identify potential safety risks and enable proactive maintenance to prevent incidents.

It provides operators with comprehensive analysis and answers all the important questions, such as How are the batteries behaving over time? What factors affect their life and reliability? Can we warn before it is too late?

Proactive Maintenance and Safety: An Example

A key aspect of battery data analysis is its role in proactive maintenance and safety. By continuously monitoring battery parameters, operators can detect early signs of deterioration or malfunction and intervene in time to avoid safety risks.

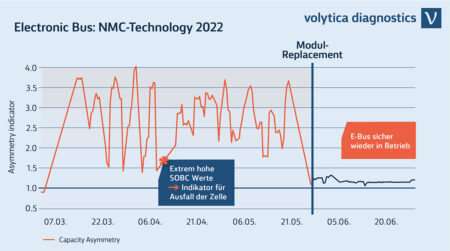

The importance of this is illustrated by the example of an electric bus: the minimum data set (VDV238) was continuously evaluated. This was available to the operator via the telematics system. The long-term trend analysis showed that the vehicle battery had a high and increasing imbalance over a period of months.

The imbalance was reported to the manufacturer by the bus operator. Following replacement of a battery module and analysis by an accredited laboratory, the manufacturer confirmed the presence of a faulty cell. Continued operation of the system, which was also experiencing unexplained spontaneous failures, would have resulted in cell failure and potentially a leak or fire.

Battery Analysis Software as a Game Changer

The power of battery data analytics is a game changer in public transport management and offers transport operators a holistic approach to improving the safety, efficiency and reliability of their fleets. The use of advanced analytics software enables proactive monitoring of the battery, mitigation of safety risks and optimization of operating parameters to extend battery life.

This is a crucial step in jointly shaping a safer, greener and more efficient future in urban transportation, especially in light of the significant skills shortage.

[1] VDV 8003: „Special contractual conditions for batteries for electric buses”, expected to be published in the course of 2024

[2] VDV 238: “Vehicle data in public transport buses”

[3] https://ec.europa.eu/commission/presscorner/detail/en/speech_21_1142